As we carry on to navigate the evolving landscape of pharmaceutical production, lyophilization stays an indispensable Resource that safeguards the potency and security of pharmaceutical products which includes biologic products for people.

"As Emergent is probably the entire world leaders in lyophilization, we trustworthy their enter and know-how to guidebook the program from development to eventual profitable existing Superior Producing Practice (cGMP) manufacturing."

The chamber is sterilized in a temperature of 121°C employing a fully validated, Laptop or computer-controlled automatic steaming technique

A freeze dryer comprises many integral parts, Every single taking part in a pivotal function while in the process. The main parts contain:

Among the most pressing issues is making certain uniformity and top quality in the lyophilized solution. Obtaining regularity could be difficult as a result of variability in freeze-drying cycles and variances in vial heat transfer. This challenge is exacerbated through the enhanced complexity of new drug products, In particular biologics.

Lyophilization is especially useful to parenteral drug builders, for a secure powder for injection might be very easily packaged and transferred to be a completed drug products. Lyophilization can even be employed to produce stable intermediates in drug product or service advancement and production.

Lyophilization, also known as freeze drying, is usually a process utilized to maintain thermolabile supplies which include pharmaceuticals and foods by getting rid of h2o from your elements when they are frozen. The process entails freezing the material, minimizing force to allow the frozen drinking water to sublimate straight from the strong period to fuel here phase, and then using reduced temperatures and pressure to remove remaining drinking water.

Making use of exact refrigeration procedures and exceptionally reduced temperatures, the aim is to attain a uniform freezing pattern through the sample.

Mass transfer then happens since the sublimation progresses within the surface down as resistance to gasoline stream boosts.

As the amount of intricate molecules inside the drug enhancement pipeline increases, An increasing number of products stand to benefit from lyophilization. Any drug developer thinking of this producing process need to be certain that they've The mixture of specialised information, services, and gear to accomplish achievement.

After the product is pre-frozen, Key drying takes area. Throughout Principal drying, the product is stored in a low temperature so which get more info the free of charge ice is sublimed faraway from the good point out under minimized tension.

We also use 3rd-social gathering cookies that help us analyze and know how you utilize this website. These cookies will likely be stored in the browser only with the consent. You even have the option to choose-out of those cookies. But opting outside of Some cookies may perhaps impact your searching expertise.

But liquid nitrogen's function won't end at fast freezing. It can also be utilized to aid in the sublimation process.

"The biological drug substance is typically not stable at two-eight°C. By changing to an ideal lyophilized sort, it's going to drastically enrich the drug material balance," states Appear.

Christina Ricci Then & Now!

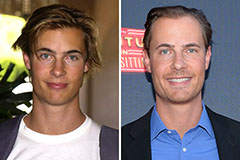

Christina Ricci Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Dawn Wells Then & Now!

Dawn Wells Then & Now!